Browse by Job:

Browse by Job:

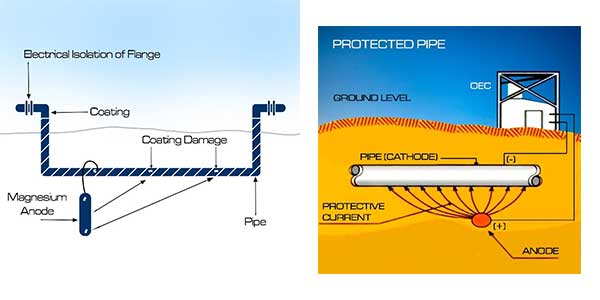

Corrosion is constantly attempting to degrade the performance of metal pipelines. The corrosion can be from dissimilar metals (galvanic corrosion), stray current corrosion from unintended sources of electricity, simple corrosion of similar metals (with varying anodic/cathodic sites), microbial induced corrosion and there are lesser-known types of corrosion.

Cathodic Protection Systems

To prevent simple corrosion and galvanic corrosion, owners of metal pipelines will often send an electrical field through the pipeline equalizing the electrical potential for all sites (this is commonly referred to as a cathodic protection system) that dramatically reduces the effects of corrosion. Owners will also coat the metal pipelines to reduce the cost of electricity needed to protect the pipeline.

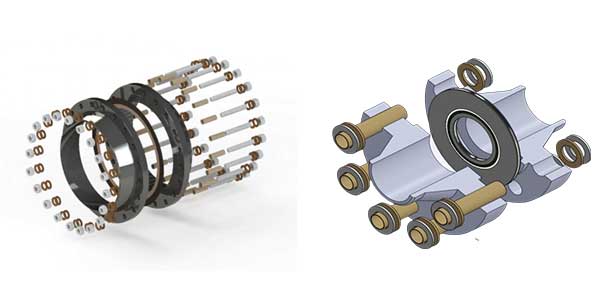

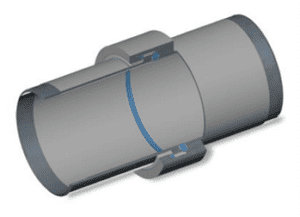

To further reduce the cost of electricity to protect the pipeline and to keep the electrical field to an effective level, isolation is often used in the form of flange isolation kits or monolithic isolation joints. Both products accomplish the same task, but flange isolation kits (FIKs) are predominately found in above ground installations while monolithic isolation joints (MIJs) are commonly found below ground. The terminology can change a bit regionally, but names like flange insulating kits, iso-kits, electrical isolation gaskets are often used to describe flange isolation kits and iso-joint, iso-block, monobloc, monoblock or insulating joint are all synonymous with monolithic isolation joints. Both FIKs and MIJs will stop the electrical flow through the pipeline and serve to keep the electricity in the areas that the pipeline owner wanted to protect. FIKs and MIJs break the metallic path in the pipeline and optimize the protection of the pipeline. Because they break the metallic path, they also stop stray current up to significant voltages. Breaking the metallic path as a function of an FIK or MIJ is very important because it will stop the electrochemical reaction between dissimilar metals. Pipelines will typically have valves, compressors, pumps, meters, pig launchers, etc. that are not made of the exact metallurgy as the pipeline itself. This difference in metallurgy brings with it differing potentials in the metals. With differing potentials and an electrolyte, the pipeline and the component are ripe to endure galvanic corrosion. By simply inserting a flange isolation kit (FIK), the metallic path between the component and the pipeline is eliminated and galvanic corrosion is then mitigated.

When an FIK or MIJ is made to the pipe bore, this can dramatically reduce microbial induced corrosion (MIC) issues. Microbe colonies will build when there is an area to hold media such as a gap between flanges. If the FIK or MIJ is made to the pipe bore, the gap is eliminated and the potential for microbial colonies to grow is dramatically reduced.

There are adjacent benefits to using FIKs and MIJs in that by decreasing the amount of electricity needed to protect a pipeline, owners will likely see reduced issues with coating disbondment, and hydrogen induced corrosion. Both of which can be caused by higher levels of electrical flow through the pipeline.

There are many types of flange isolation kits and monolithic isolation joints on the market today. It is recommended that if the pipeline is carrying a flammable material that a fire safe flange isolation kit be used. If chemicals are added to the media to reduce microbial colonies from forming, to act as surfactants, to reduce iron sulfide build-up or for any other reason or if chemicals such as hydrogen sulfide are part of the media stream, it is important that the isolation kit is chemically compatible with the chemicals being used.

Today, many companies are attempting to achieve greenhouse gas emission reduction goals. If the pipeline is part of that effort, it is recommended that glass reinforced epoxy (GRE) based isolation gaskets and phenolic isolation gaskets BE AVOIDED as these materials are permeable. It is also recommended that when an isolation product is used (either flange isolation kit or monolithic isolation joint), that a pipeline decoupler also be used to mitigate stray current or lightning effects that are beyond the capabilities of the isolation kit or joint.

A common flange isolation kit will consist of an isolating gasket, an isolating sleeve and isolating washers (preferably fully coated and encapsulated stainless steel washers).

Stay in touch with GPT through our network of sales professionals, engineering experts, manufacturing locations or distribution partners. We want to hear from you. Feel free to contact us if you have questions, big or small, we’re here to help.